The subsequent article helps you understand the Top Benefits of Silicone extrusion.

Silicone extrusion

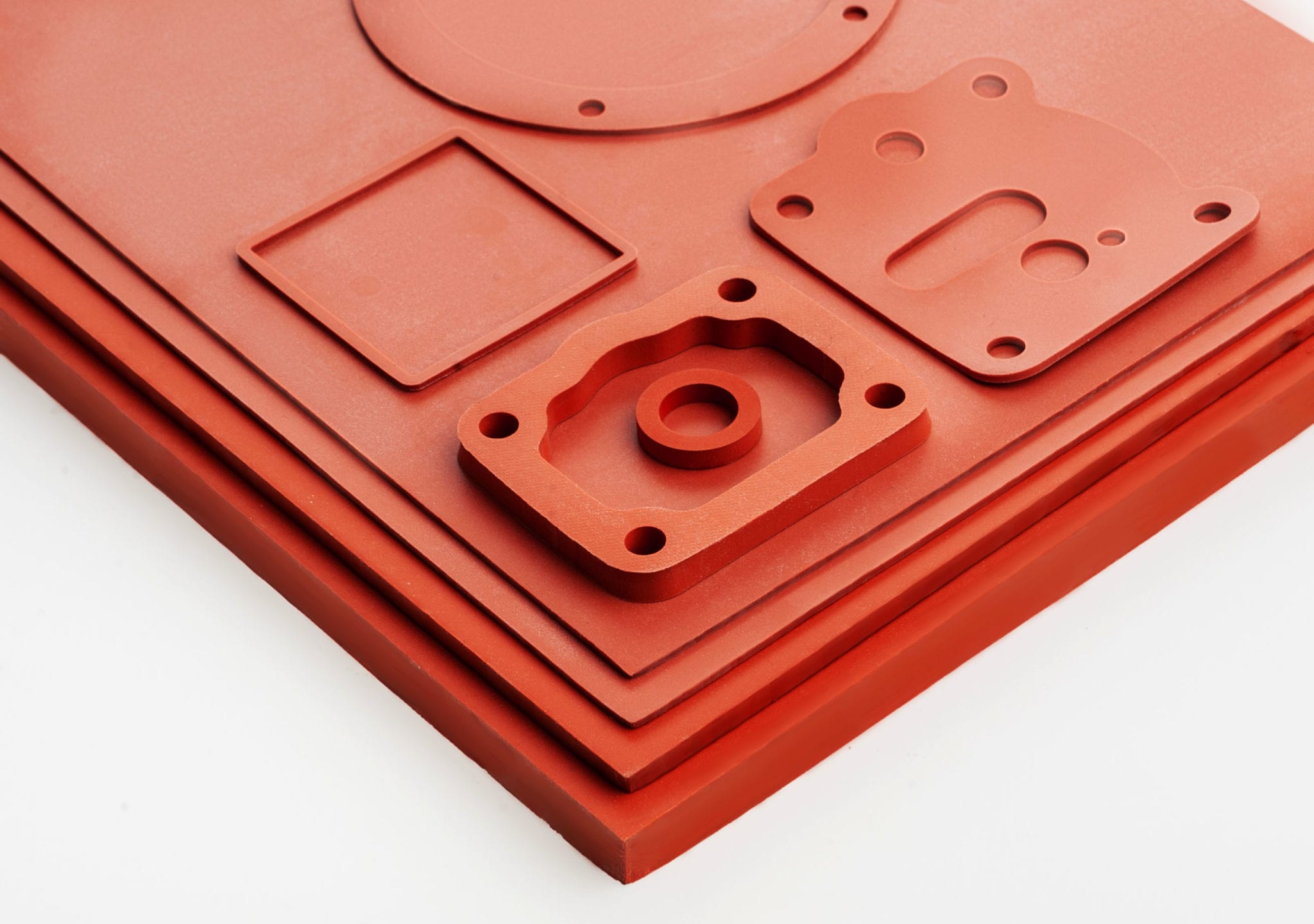

silicone tube manufacturer are forced through a shaped die in silicone extrusion to produce a continuous piece of material with complex profiles and cross-sections. Silicone’s elastic properties make it an ideal material for use in electronics.

Custom Silicone Extrusions

As custom silicone manufacturers capabilities have improved over the last 30 years, custom silicone extrusion has become more accessible. As a result, silicone has become the go-to elastomer for use in engineered products.

Engineers, manufacturers, and inventors regularly use our tubing, cords, and bands, as well as molded products made from solid silicone and other elastomers. We also produce open-cell and closed-cell silicone foam.

As a result of the extrusion process, the finished product can be manufactured in continuous lengths or cut to size and packaged to suit the customer’s needs. We can also imprint your product information, logos, and graphics on the finished product.

Using custom silicone solutions has become a popular option for meeting the extreme operating conditions in many major industries. At Tech-Link Silicone, we utilize extensive silicone extrusion capabilities to provide our customers with solutions for overcoming various operational challenges.

Various silicone components can be produced through extrusion, but these characteristics are common to all silicone extrusions:

- Biocompatibility

As a general rule, silicone is non-toxic and non-allergenic, making it ideal for use in medical devices since it will not cause adverse reactions when it comes into contact with human skin or tissue.

- Good chemical resistance

It’s easy to clean and can be used in various processes since silicone is inert and won’t react with most chemicals. Although some concentrated acids may break down silicone, it’s essential to check the compatibility of the chosen material with application-specific chemicals.

- Excellent elastic memory

After being subjected to high pressures or compressive forces, silicone constantly strives to return to its original shape.

- Great dielectric strength

In general, extruded silicone and silicone sponge materials act as good electrical insulators and will not break down or become conductive when exposed to regular current.

- Transparent and translucent

The relatively straightforward nature of extruded silicone makes it ideal for applications that need specific colors or aesthetics, as well as for precise tubing fabrication.

- Resistant to high temperatures

Silicone extrusions can handle temperatures as high as 500°F.

Tech-Link is amongst the best Silicone extrusion manufacturers specializing in creating custom silicone extrusion products to meet virtually any requirement. Our manufacturing processes adhere to many industry standards, and we can also develop unique formulations for specific applications.

We have more examples of our work on our website. If you are interested in working with us, please contact us or request a quote.